Prototyping

WE BUILD REALISTIC PRE-PRODUCTION PROTOTYPES THAT LOOK, FEEL, AND PERFORM LIKE THE REAL THING.

WE BUILD REALISTIC PRE-PRODUCTION PROTOTYPES THAT LOOK, FEEL, AND PERFORM LIKE THE REAL THING.

WE BUILD REALISTIC PRE-PRODUCTION PROTOTYPES THAT LOOK, FEEL, AND PERFORM LIKE THE REAL THING.

WE BUILD REALISTIC PRE-PRODUCTION PROTOTYPES THAT LOOK, FEEL, AND PERFORM LIKE THE REAL THING.

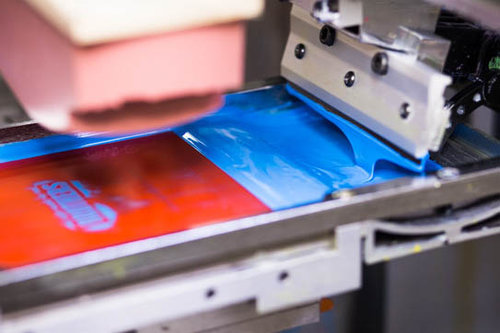

At Artek Industries, we believe that prototyping is an art and a science — from specifying the correct tolerances and materials during the design phase, to post-processing each and every prototype we create by hand and by machine — our deliverables are as close to the real production piece as possible. We take pride in our high-quality prototypes and stand behind our work on each and every one of them.

DELIVERABLES: 1 to 100 physical prototypes

AVAILABLE SERVICES: CNC machining, 3D printing, resin casting, thermoforming, PCB fabrication, PCB assembly

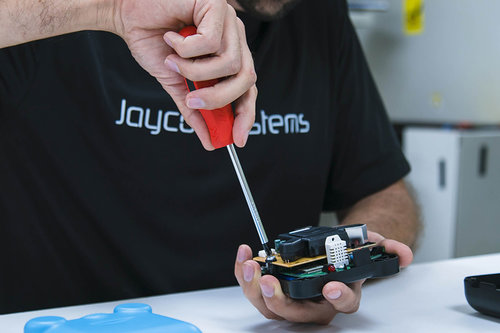

We can fabricate your boards and assemble them by hand for low volume batches or by machine for high volume batches when set up in panels.

Requirements: design file (Gerber) and BOM (bill of materials).

Capabilities: up to 14 layers, through-hole or surface mount, flex PCB.

We can fabricate your boards and assemble them by hand for low volume batches or by machine for high volume batches when set up in panels.

Requirements: design file (Gerber) and BOM (bill of materials).

Capabilities: up to 14 layers, through-hole or surface mount, flex PCB.

At Artek Industries, we believe that prototyping is an art and a science — from specifying the correct tolerances and materials during the design phase, to post-processing each and every prototype we create by hand and by machine — our deliverables are as close to the real production piece as possible. We take pride in our high-quality prototypes and stand behind our work on each and every one of them. Our multi axis computer numeric control machines mill away material at extremely high resolution for accurate tolerances.

Requirements: STEP/STP file

Materials: plastic (ABS, PC, POM, PMMA, nylon, and more), hard resin (clear, white, black, grey), metal (aluminum, brass, stainless steel). Other materials upon request.

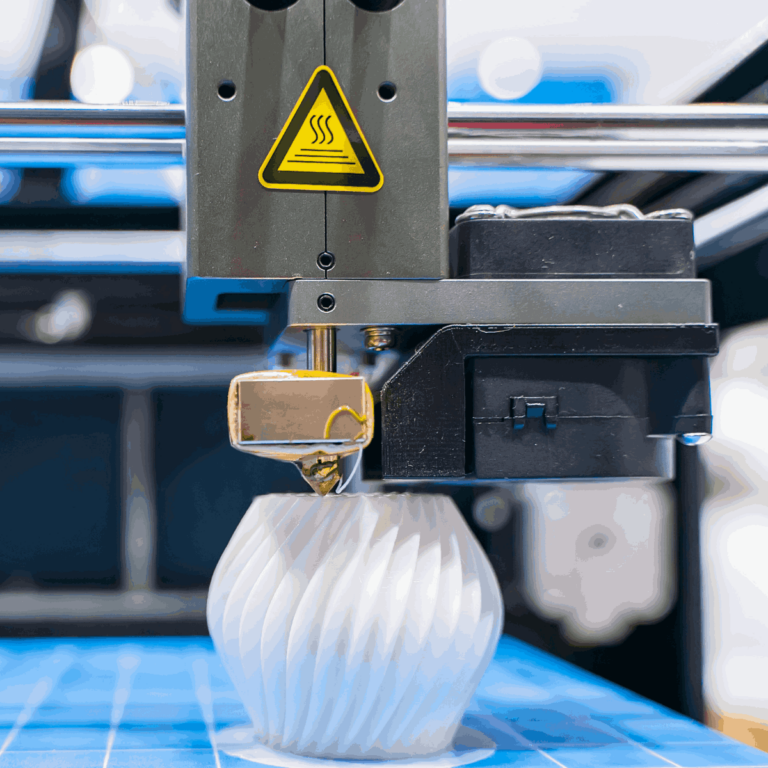

Artek Industries has four state-of-the-art 3D printers that allows our engineers to create realistic prototypes quickly.

Requirements: STL file

Materials: PLA, ABS, CPE, PC, Nylon, TPU 95A, PP, PVA and more.

Tolerance: Layers as thin as 32 microns (0.032 millimeters).

Artek Industries has four state-of-the-art 3D printers that allows our engineers to create realistic prototypes quickly.

Requirements: STL file

Materials: PLA, ABS, CPE, PC, Nylon, TPU 95A, PP, PVA and more.

Tolerance: Layers as thin as 32 microns (0.032 millimeters).

Our team is able to create prototypes faster and more inexpensively than other processes with resin casting.

Requirements: existing prototype

Materials: over 50 types of resins

Restrictions: parts bigger than 8 inches may not be suitable for this prototyping process.

We take into consideration the requirements of the client, part size/complexity, product application, and other factors to ensure the file is best optimized to the prototyping process used for fabrication.

With many prototyping methods to choose from, our engineers pick the most optimal process and carefully set up the machinery, overseeing the process to ensure fabrication is as smooth as possible.

It’s rare that prototypes are ready as-is after fabrication. Our team of prototype specialists ensure care in the post processing of the prototype so it looks and performs like the real manufactured unit.

And be one step closer to starting production without any unforeseen manufacturing difficulties.